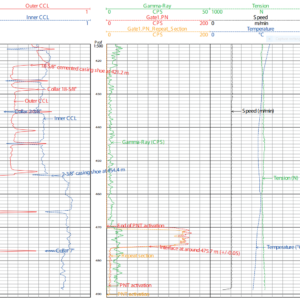

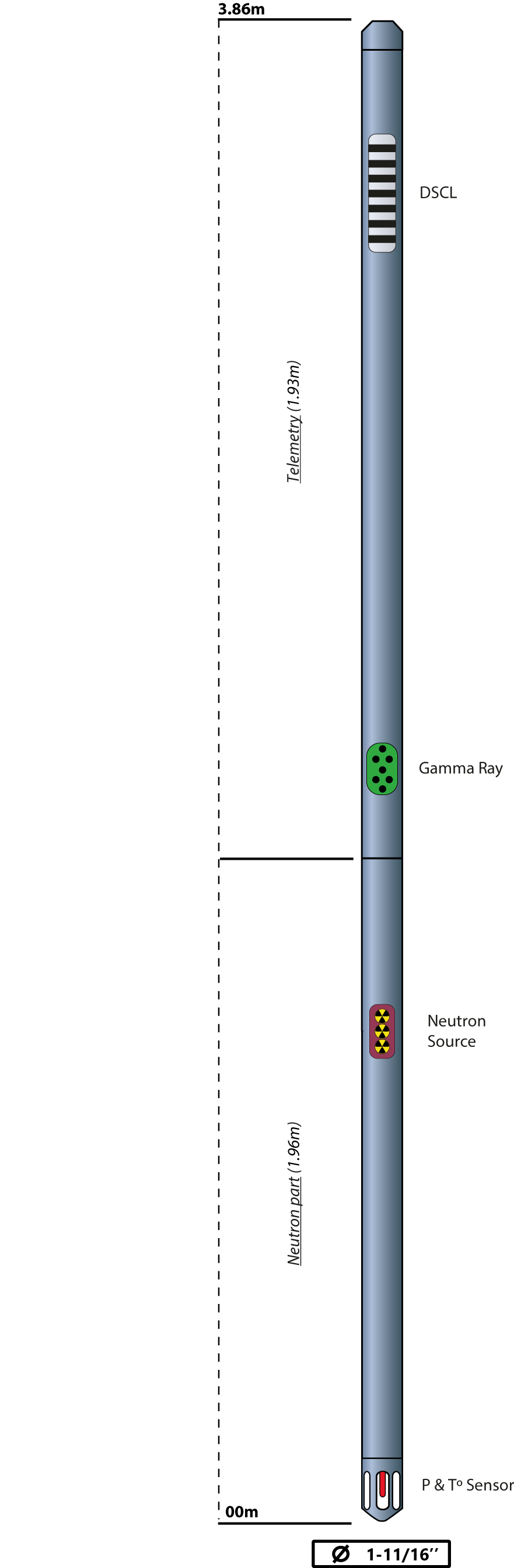

The Pulsed Neutron Tool is a dedicated instrument used to determine the brine – hydrocarbon interface in storage cavities, to control the blanket level in solution mined caverns and to run Mechanical Integrity Tests. The instrument

incorporates a Neutron generator which is electrically activated in the cavity and a fast/efficient Gamma-Ray detector. As brine has a much higher neutron capture capability than hydrocarbons, the interface is easily detected when

crossed while pulling out the logging string.

The instrument also includes a Dual String Collar Locator in order to accurately correlate depth at cemented casing shoe even behind two strings and a Temperature sensor to identify any abnormal behavior while running in.