Initial Prototype : September 2021

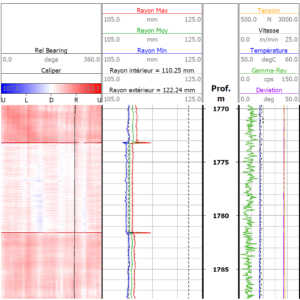

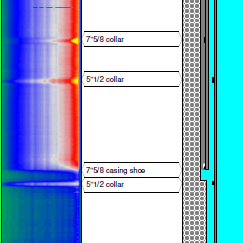

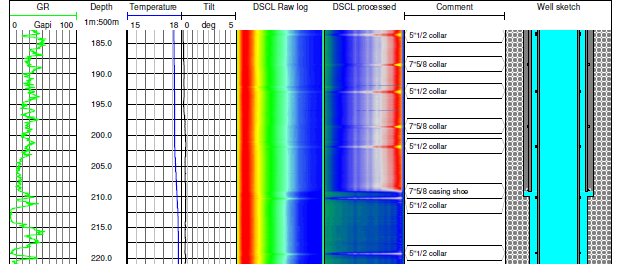

The idea of FLODIM Corrosion Evaluation Tool came after evidence that casing cuts percentage of success and necessary times were dependent on the quality of the information provided. Therefore, it proved more than interesting to assess the real state of the pipe in order to be aware of any evolution from initial standard conditions, such as ovoid shape, deposits, inner corrosion or any local damage.

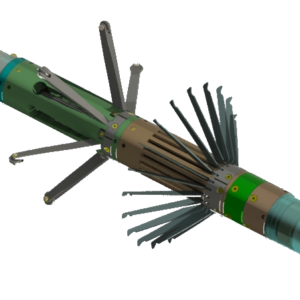

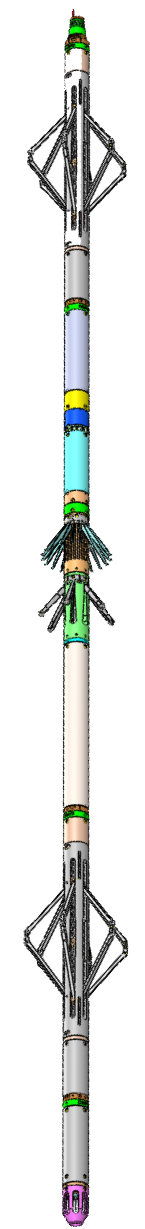

Run on a standard electric logging cable, the main components and functions of the Corrosion Evaluation Tool are as follows :